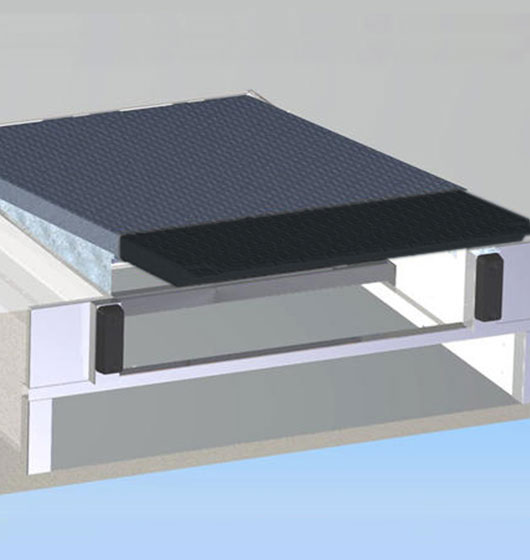

Ramp with telescopic lip

Home / Campisa Loading Bays / Ramp with telescopic lip

Loading ramps ideal for vans: electro-hydraulic ramp with telescopic lip, robust and durable, allows the loading-unloading of vehicles in a safe and rapid way. Pit height must be 550 mm. Assembly with simple accessories in a traditional pit. Windproof head zip, with continuous connection.

Maximum connection inclination of 12.5% as per EN 1398 (anti-slip inclination). Campisa suggests an inclination limit of 8% for forklifts and 4% for electric pallet trucks.

Maximum lifting above the quay level: about 400 mm

Maximum lowering below the quay level: about 350 mm

Torsion, 3% adaptation to the inclination of the platforms as per EN 1398, following the lateral inclination of vehicles.

LOADING RAMP SPOUT

- Telescopic opening.

- High resistance 12 + 2 mm checkered plate to the floor, chamfered at the front end. Internal part made by 6 + 2 mm thk. checkered plate.

- Length 500 or 1000 mm adjustable.

- 2000 mm width in one piece for ramps 2000 mm wide.

- 2200 mm width in three pieces (130 + 1930 + 130) for ramps 2200 mm wide.

- Made by 6 + 2 mm checkered plate, anti-slip and self-draining.

- Supported by high strength steel side elements.

- Standard rounded windproof head zip at any connection angle.

- Lifting is obtained with a 60 mm diameter hydraulic cylinder.

- Opening and closing of the spout are activated by a double-acting hydraulic cylinder, which manages also the return to rest position, safely.

- Shipping height: from 180 to 550 mm according to the ramp model.

- Handling by crane or by forks with disposable hooks above the platform.

The 2000 mm wide ramps, can be provided with 2 self-releasing side flaps 130 mm wide on each side, for the connection to reduced floors.

- Option 1: spout prolonged 430 mm from the edge of the quay to full extension.

- Option 2: lifting cylinders with diameter = 40 mm (requires higher pit, see drawing).

- Option 3: windproof seal on both sides of the ramp (windproof head is standard).

- Option 4: hot-dip galvanized ramp and spout.

In compliance with the provisions of EN 1398, the ramps are equipped with:

- Automatic valve to block the descent in case of unexpected departure of the vehicle.

- Solenoid block valve controlled by power supply shut-off switch.

- Movable side foot guards.

- Maximum pressure safety valve.

- Non-slip and self-draining checkered steel sheet.

- Minimum 25 mm between folded spout and resting support.

- Positive locking system of the raised ramp, for safe operation.

- Rounded windproof head zip, allows the passage without jolts in any connection position.

The standard nominal capacity of loading ramps for vans is 6,000 kg (10,000 kg evenly distributed).

On request we provide ramps with a nominal capacity of 9,000 kg (15,000 kg evenly distributed).

The electro-hydraulic operation of the loading ramps requires connection to the electrical network, the standard models have a three-phase 230/400 V, 50/60 Hz power supply. Power units with different power supply, and voltage can be provided.

Request a free quote

Request a free quote

Contact us for a free consultation and find out the best logistics solutions for your needs.